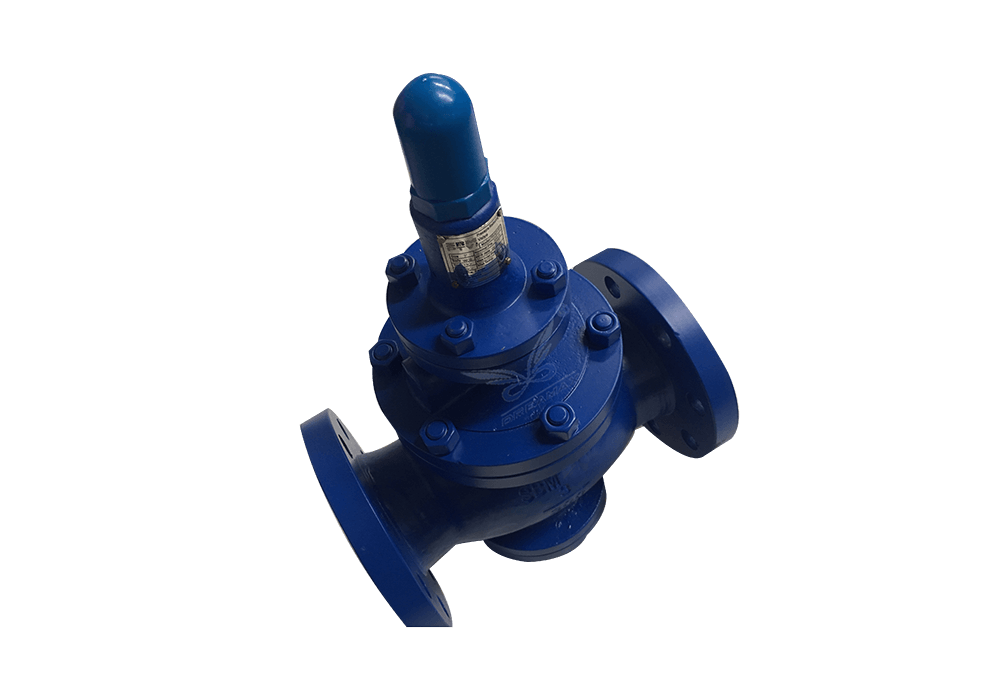

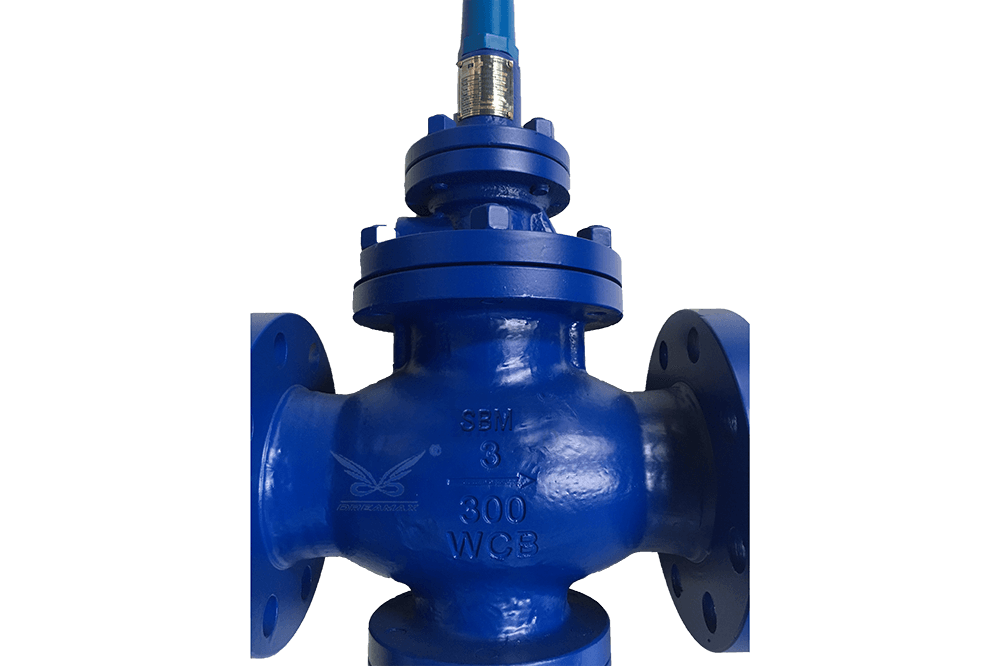

Pressure Reducing Valve RF

- Tel: 0086-21-53021748

- E-mail: export@shdreamax.com

-

Size range:1/2" - 16"

Body design conditions: 150LB / 300LB / PN16 / PN25 / PN40

Maximum inlet pressure: 300LB / PN40 : 50 Bar @ 40℃

150LB / PN25 / PN16: 25 Bar @ 40℃

Maximum design temperature: 350℃@ 24 Bar

Minimum design temperature: -29℃

Outlet Pressure Range:300LB / PN40 : 3~20 Bar

150LB / PN25 / PN16: 3~16 Bar

Maximum operating temperature: 325℃@ 24 Bar

Maximum temperature instantaneous : 425℃

Outlet pressure deviations : ≤±0.5 Bar

Minimum pressure differential: 2 Bar

Suitable Medium: Suitable for steam, gas, compressed air. etc

Pressure Reducing Valve RF PRV425 general situation

When the pressure reducing valve is released from the factory, its adjusting spring is in an uncompressed state while its main valve and pilot valve disc are in the closed state. To use it, rotate the adjusting screw clockwise to compress the adjusting spring and make the diaphragm move down to open the pilot valve disc. The medium flows from the orifice A to the orifice B through the pilot valve seat and then into the area above the piston. Acted by the medium pressure, the piston moves down to drive the main valve disc to leave the main valve seat and make the medium flow to the outlet of the valve and meanwhile through the orifice C and into the area below the diaphragm. When the outlet pressure exceeds the set value, it will push the diaphragm upwards to compress the adjusting spring. Then the pilot valve disc will move in the closed direction to reduce the medium flowing to the area above the piston, and the pressure will drop as well; here the main valve disc will be pushed by the main valve disc's spring force to move upwards to reduce the clearance between the main valve's disc and seat while the medium flow will reduce as well and the outlet pressure will also drop to strike a new balance. Contrarily, when the outlet pressure is lower than the set value, the clearance between the main valve's disc and seat will increase and the medium flow will increase as well so that the outlet pressure will increase to strike a new balance.

Features

1. Self-acting using spring and piston operation - no need for electrical supplies.

2. Internally piloted piston-operated.

3. Self-aligning feature allows the piston to move smoothly, resulting in

accurate responsive control.

4. Stable outlet pressure can be maintained, even with fluctuations in upstream pressure or flow rate.

5. Accurate control of pressure with one spring.

6. Stainless steel internals for excellent durability and resistance to corrosion.

7. Wide range of screwed and flanged connections to match plant standards.

8. Metal-to-metal seat

2. Internally piloted piston-operated.

3. Self-aligning feature allows the piston to move smoothly, resulting in

accurate responsive control.

4. Stable outlet pressure can be maintained, even with fluctuations in upstream pressure or flow rate.

5. Accurate control of pressure with one spring.

6. Stainless steel internals for excellent durability and resistance to corrosion.

7. Wide range of screwed and flanged connections to match plant standards.

8. Metal-to-metal seat

Performance Standard

1. Design & Manufacture standard as to: ASME PTC 25.3 / ASME B16.34

2. Face to Face dimension standard as to: MFR-STD

3. Flange dimension conforms as to: ASME B16.5 / BS EN 1092

Threaded Standard as to: NPT : ASME B1.20.1

BSP : ISO 7-2: 2000

4. Testing and inspection as to: API 598 / ASTM E 1008-2003

5. Pressure-temperature conforms as to: ASME B16.34

6. Anti Corrosion as per NACE MR-0175(2002) requirement

2. Face to Face dimension standard as to: MFR-STD

3. Flange dimension conforms as to: ASME B16.5 / BS EN 1092

Threaded Standard as to: NPT : ASME B1.20.1

BSP : ISO 7-2: 2000

4. Testing and inspection as to: API 598 / ASTM E 1008-2003

5. Pressure-temperature conforms as to: ASME B16.34

6. Anti Corrosion as per NACE MR-0175(2002) requirement

Related Product

Valves

- Air Release Valves

- Three Functions Air Valve/ Combination Air Release Valve (FOX)

- Wastewater Air Valve/ Combination Sewage Air Valve (Gamm HP)

- High Anticorrosive Air Valve/ Combination Inner Lined Air Valve

- Two Functions Air Valve/ Air Release Valve(Omega)

- Two Functions Air Valve/ Inner Lined Sewage Air Valve(Omega HP)

- Combination Lined Sewage Air Valve (Delta HP)

- Micro-Air Release Valve/Automatic air release valve (A200)

- Pressure Reducing Valves

- Ball Valves

- Butterfly Valves

- Strainers

- Check Valves

- Pinch Valves

- Diaphragm Valves

- Knife Gate Valves

- Safety Valves

- Steam Traps