- Tel: 0086-21-53021748

- E-mail: export@shdreamax.com

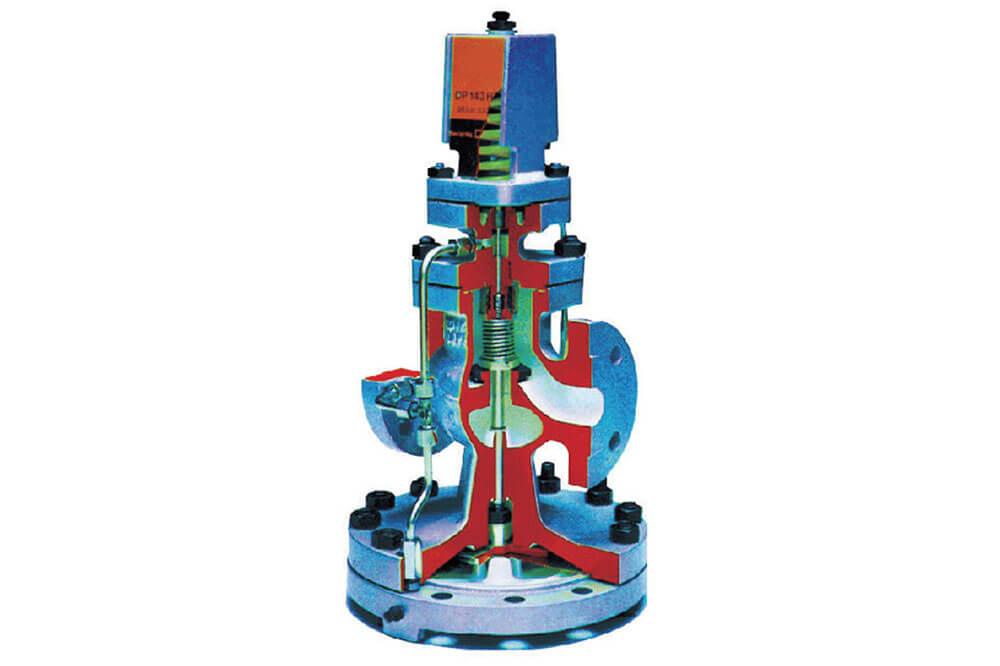

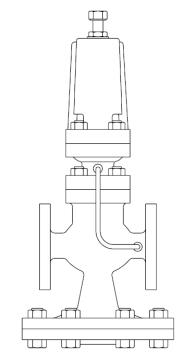

Pressure Reducing Valve DP143

Red: 0.5 Bar to 2 Bar

Blue: 2 Bar to 10 Bar

Yellow:-10 Bar to 25 Bar or 40 Bar

The DREAMAX pressure reducing valve DP143 is a self-powered, pilot-operated (externally piloted). Its self-acting operation eliminates the cost of an external power source. It constructed of carbon steel, suitable for steam, air or industrial gases. The DP143 will accurately control downstream pressure, regardless of the upstream pressure, or load variations.

The DP143 offers a wide range of control options. Color coded, interchangeable springs allow quick and easy change of downstream pressure range eliminating the need to isolate the valve or break the steam line. Downstream pressure is sensed either internally or through an external sensing pipe.

These are recommended for medium duty or process type applications, branch lines to OEM equipment, for accurate process control or where an external interface or remote adjustment is required. Typical applications include main line pressure reduction or where high accuracy of control is required. It combines high accurate control with increased resilience to harsh operating environments, easier servicing and simpler selection. This versatile and compact valve will provide an efficient and economic solution in many pressure reduction applications.

- 1.Self-acting using spring and diaphragm operation - no need for electrical supplies.

- 2.Accurate control of pressure with choice of color coded springs.

- 3.Stainless steel internals for excellent durability and resistance to corrosion.

- 4.Wide range of screwed and flanged connections to match plant standards.

- 5.Fatigue tested diaphragm -no piston, no danger of sticking.

- 6.Extended valve life due to an externally accessible, easily replaced

- pilot filter.

- 7.Easily serviced using off-the-shelf spares and standard tools.

- 8.Metal-to-metal seat

2.Face to Face dimension standard as to: MFR-STD

3.Flange dimension conforms as to: ASME B16.5 / BS EN 1092 Threaded Standard as to: NPT : ASME B1.20.1 BSP : ISO 7-2: 2000

4.Testing and inspection as to: API 598 / ASTM E 1008-2003

5.Pressure-temperature conforms as to: ASME B16.34

6.Anti Corrosion as per NACE MR-0175(2002) requirement

|

Technical Data |

||

|

1. Size range: NPS 1/2" ~ 2" |

||

|

2. Body design conditions: 150LB / 300LB / PN16 / PN25 / PN40 |

||

|

300LB / PN40 : 50 Bar @ 40℃ |

||

|

150LB / PN25 / PN16: 25 Bar @ 40℃ |

||

|

5. Minimum design temperature: -29℃ |

||

|

6.Outlet Pressure Range |

300LB / PN40 : 0.5~40 Bar |

|

|

150LB / PN25 / PN16: 0.5~16 Bar |

||

|

7. Maximum operating temperature: 325℃@ 24 Bar |

||

|

8. Outlet pressure deviations: ≤±5% |

||

|

9. Minimum pressure differential: 1.5 Bar |

||

|

10. Suitable Medium: Suitable for steam and compressed air. |

||

- Air Release Valves

- Three Functions Air Valve/ Combination Air Release Valve (FOX)

- Wastewater Air Valve/ Combination Sewage Air Valve (Gamm HP)

- High Anticorrosive Air Valve/ Combination Inner Lined Air Valve

- Two Functions Air Valve/ Air Release Valve(Omega)

- Two Functions Air Valve/ Inner Lined Sewage Air Valve(Omega HP)

- Combination Lined Sewage Air Valve (Delta HP)

- Micro-Air Release Valve/Automatic air release valve (A200)

- Pressure Reducing Valves

- Ball Valves

- Butterfly Valves

- Strainers

- Check Valves

- Pinch Valves

- Diaphragm Valves

- Knife Gate Valves

- Safety Valves

- Steam Traps