- Tel: 0086-21-53021748

- E-mail: export@shdreamax.com

-

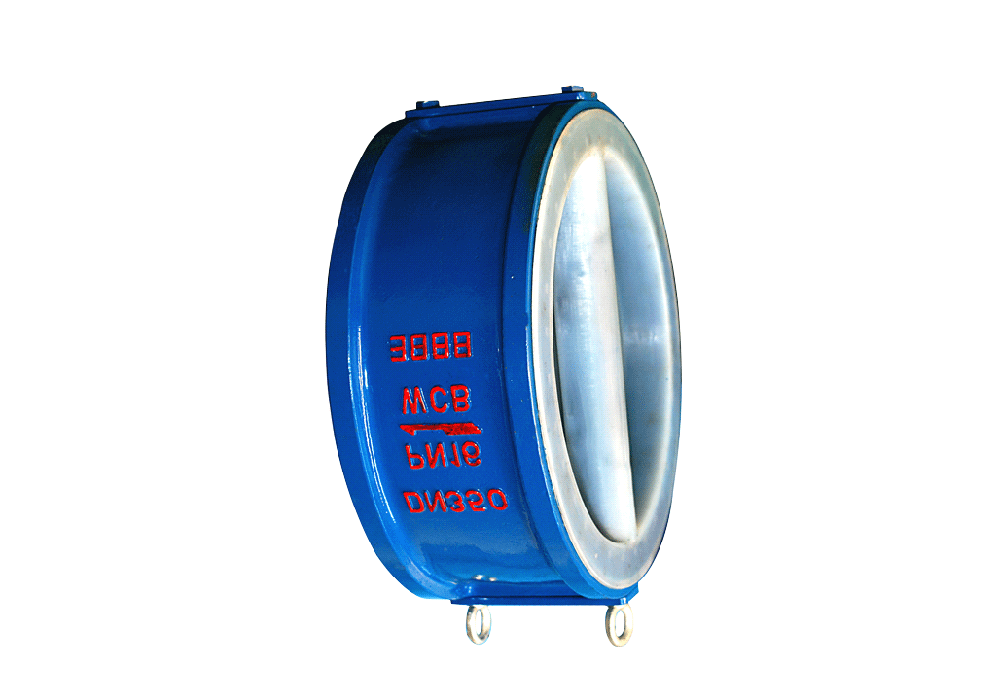

Lined PFA Dual Wafer Check Valve

Size range: NPS 2" ~ 14"

Pressure ratings: 150LB

Working temperature: -29℃ ~ +120℃

Body Material: A216 WCB lined PFA

Disc Material: A351 CF8M lined PFA

Spring Material: A276 SS304 Lined PFA

Stem Material: A276 SS304 Lined PFA

DREAMAX Fully lined PFA wafer dual check valve are ideal for use in totally lined piping systems or to replace costly high alloy steel valves in high corrosion applications. The valve can be mounted horizontally or vertically with upward flow. The PFA lining locked by grooves allow the valve body to be used on high pressure and temperature without lining collapse, shrinkage and blowout. Also it is virtually unaffected by changes in processing operation or chemical concentration like chloride, sulfuric acid and mixed acid.

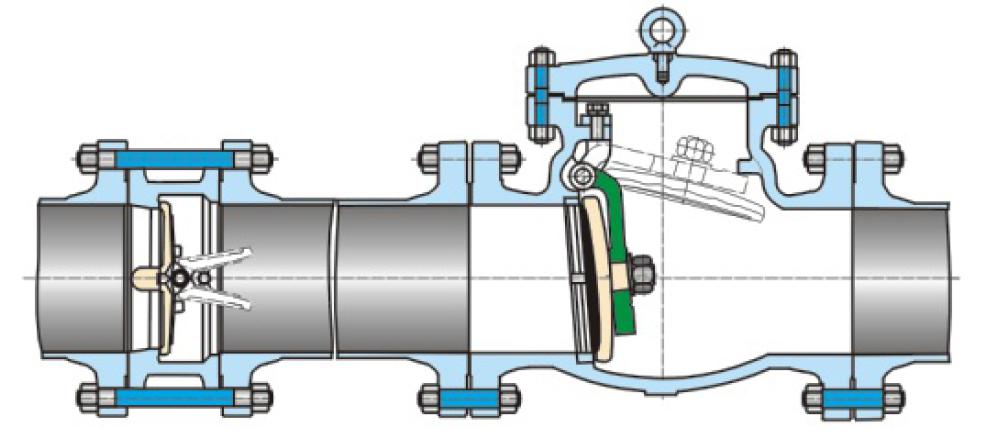

How it works: Double plate check valves are spring loaded. When the pump starts and the downstream flow creates the required pressure drop in the forward direction, the double plate will automatically open. When the pump stops and the flow ceases, the torsion of the spring will automatically close the double plate prior to flow reversal. This creates a positive shut-off against flow reversal and minimizes system surges and water hammer.

PFA

PFA is a fluoropolymer with extended temperature limits. It is a copolymer that combines the carbon-fluorine backbone of fluorocarbons with a perfluoroalkoxy side chain.

PFA offers a variety of attributes and benefits:

1.Handles a wide range of fluids .

2.Chemically inert . Heat resistant .

3.Weather resistant .

4.Stress-cracking resistant .

5.Negligible moisture absorption

6.Better sealing and wear resistance between parts -because it is moldable and machinable to close tolerances.

7.PFA is a true thermoplastic and is melt processible, so it can be locked to the valve components. Blow-out or liner collapse are virtually impossible.

1.Cost efficient design

Short structural length, only 1/4 - 1/8 of that of traditional flanged check valve.

Low volume, light weight, only 1/4~1/20 of those of traditional flanged swing check valve.

Wafer Dual Check Valve Flange Swing Check Valve

2.Fully Lined PFA

Body, disc, spring and stem all lined PFA

3.Locked-in lining

The PFA lining have cast dovetail recesses and machined grooves that lock the lining to the body casting. Blow-out or liner collapse are virtually impossible.

4.Minimal head loss

The contoured body of the Valve provides a short and straight flow path that generates very little turbulence. Additionally, the spring-loaded discs are designed with very low cracking pressure which reduces the amount of energy required to open the valve.

5.Quick Close to Reduce Water Hammer

Shut-off is achieved via the fully automatic, spring-assisted discs that close near zero flow velocity. The lightweight, split disc design creates a positive shutoff prior to flow reversal and helps minimize valve slam and surge.

6.Applicable for and easily installed for vertical or horizontal pipelines.

7.Flexible action and good sealing performance.

8.Narrow valve travel and small closedown impact.

9.Long service life and good reliability.

2.Face to Face dimension standard as to: MFR-STD

3.Flange dimension conforms as to: ASME B16.5 RF

4.Testing And Inspection as to: API 598

5.Anti Corrosion as per NACE MR-0175 requirement

- Air Release Valves

- Three Functions Air Valve/ Combination Air Release Valve (FOX)

- Wastewater Air Valve/ Combination Sewage Air Valve (Gamm HP)

- High Anticorrosive Air Valve/ Combination Inner Lined Air Valve

- Two Functions Air Valve/ Air Release Valve(Omega)

- Two Functions Air Valve/ Inner Lined Sewage Air Valve(Omega HP)

- Combination Lined Sewage Air Valve (Delta HP)

- Micro-Air Release Valve/Automatic air release valve (A200)

- Pressure Reducing Valves

- Ball Valves

- Butterfly Valves

- Strainers

- Check Valves

- Pinch Valves

- Diaphragm Valves

- Knife Gate Valves

- Safety Valves

- Steam Traps